This is a basic Guide to help with installation. There may be small differences over different models years, but the setup is very similar. Remember this is a standalone ecu and some tuning/setup is required.

*Disclaimer*

*Please note You are going to be touching electrical components, fuel system and fuel which is flammable. Please take all the necessary safety precautions required and have a fire extinguisher on hand. BillT Industries assumes no liabilities or responsibility for any damages that may occur during the installation and tuning of this kit. It is the sole responsibility of the end user or installer to make sure this kit is installed and tuned properly*

Software Download - Downloads (tunerstudio.com)

Ultra Software - https://www.tunerstudio.com/index.php/products/tuner-studio/tsarticles/119-tunerstudio-30-feature-matrix

The lite free version of ms is very limited. I recommend purchasing/registering the Ultra software for full feature and logging access all in one program

-

This is the optional external map sensor for the easy install kit. It will connect/tee into the vac line on the intake manifold

-

This is the adapter for the basic kit with afm delete. It has the iat sensor only

-

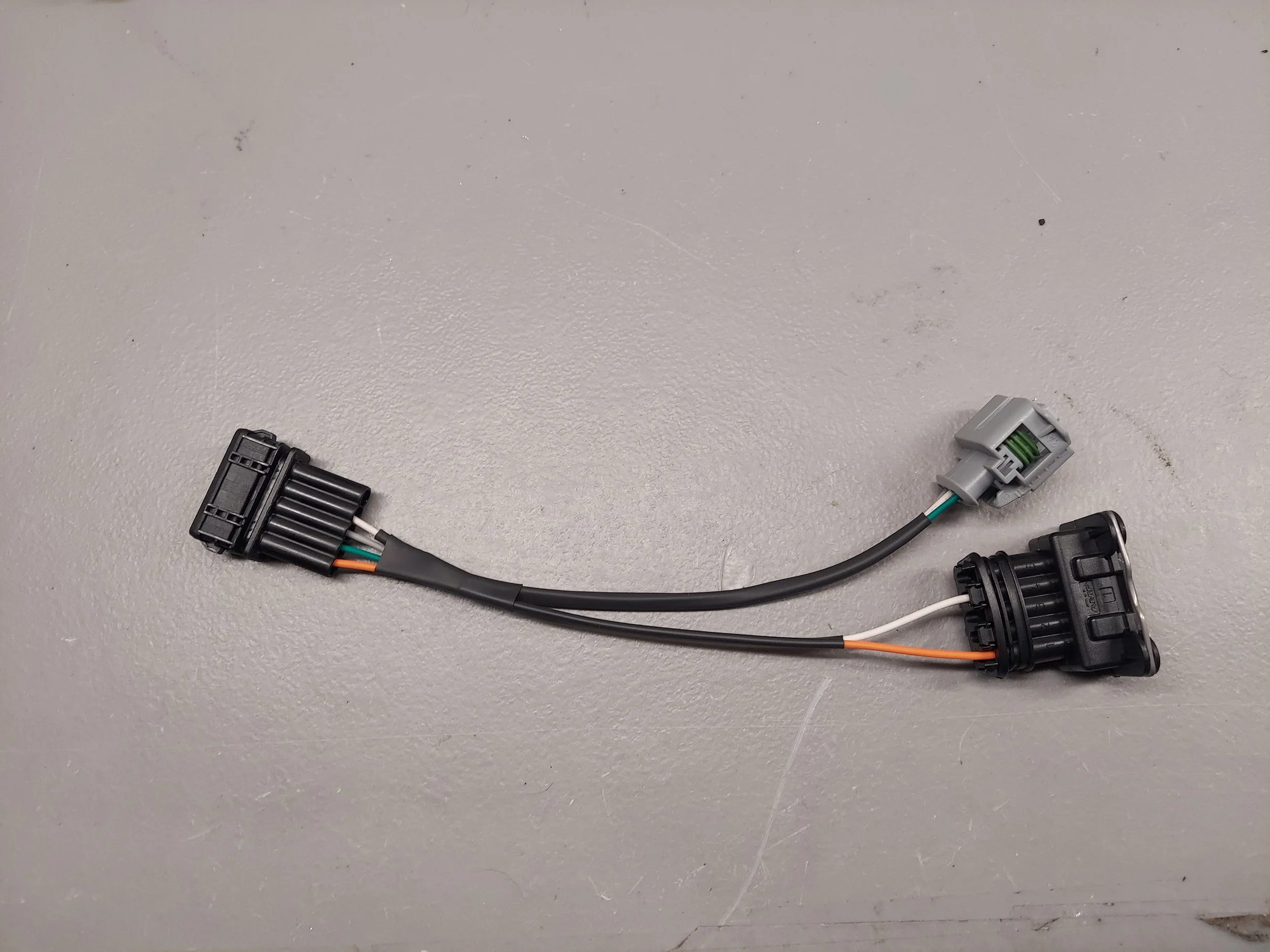

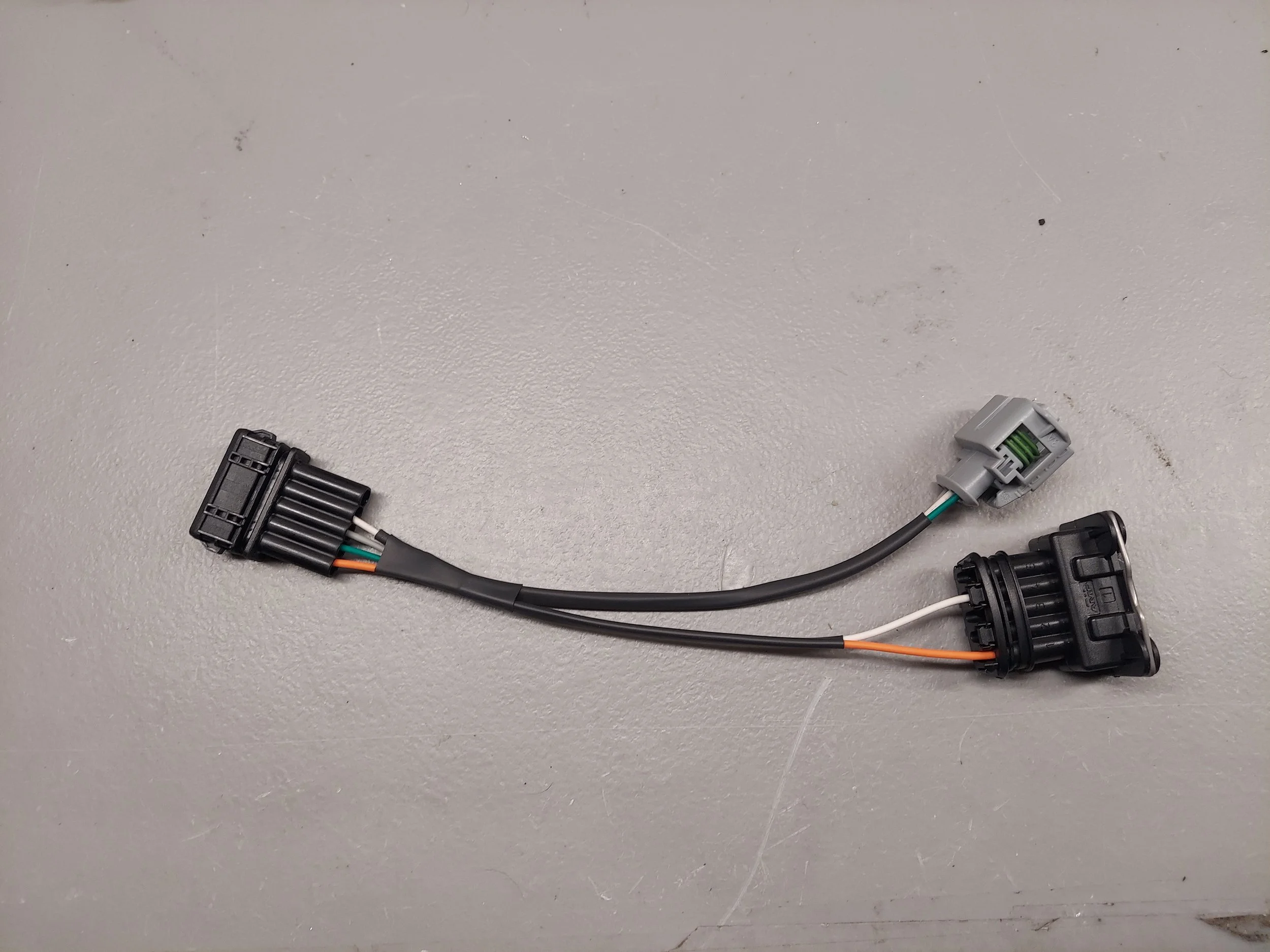

This is the adapter harness on the easy install kit for an afm delete. It has the external map sensor and Iat sensor

-

This is the adapter harness on the easy install kit for keeping the stock afm. It has the external map sensor only

-

This is the shortened pnp wideband on the easy install kit. It plugs into your original o2 sensor plug

-

This is the windband controller on regular kits. There will be two of these for dual wideband kits

-

This is the wideband o2 sensor. This will replace the original o2 sensor. There will be two of these for dual wideband kits

-

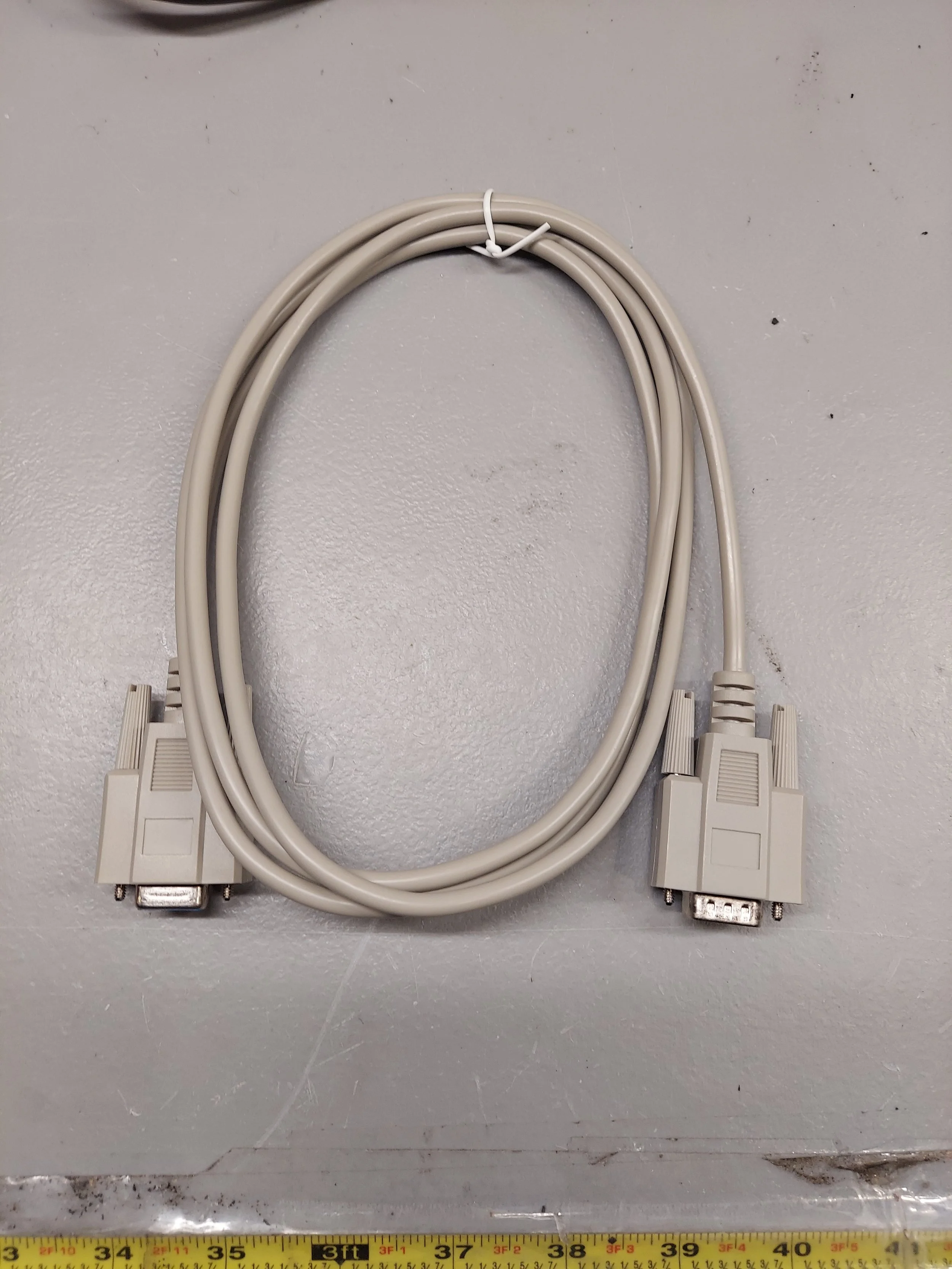

This is the data com cable. It will install on the back of the ecu

-

This is an extension harness for the data cable to the ecu. It is usually not needed

-

The 964 pnp ecu kit is fairly straight forward to install. The Easy install kit is designed for cars running only One o2 sensor to cut down on install time. If you are going to be running more than one o2 sensor or any other additional options (dual o2, fuel psi, boost control, COP, DBW) Then the base kit is recommended since you will be having to run the wiring for add on components into the car to the ecu

-

First up is probably the hardest part of the install, removing the old o2 sensor. It is usually easiest to jack the car up and remove the wheel to get better access. Sensors can get seized over time so it maybe necessary to heat it up for removal. Do at your own risk.

You will need to drill the hole bigger for the old o2 sensor wiring in the engine tin in order to install the new o2 sensor. Usually a step bit with 7/8” is big enough. The new o2 sensor will get run through the tin from the engine bay side out to the exhaust. This will keep the hole being drilled down to a minimum size.

-

If you have the basic install kit or any add on options you will need to remove the Drivers seat, rear seats, parcels shelf, and driver side quarter panel cover. This will give the best access for running the additional wiring and vac hose to the ecu.

If you have the easy install kit you will only have to remove the drivers seat for ecu install

-

The wideband controller will get zip tied up to the original engine harness on top of the frame rail.

The basic kit will require running the wiring through the firewall into the car.

The easy install kit will connect to the original o2 sensor connector

-

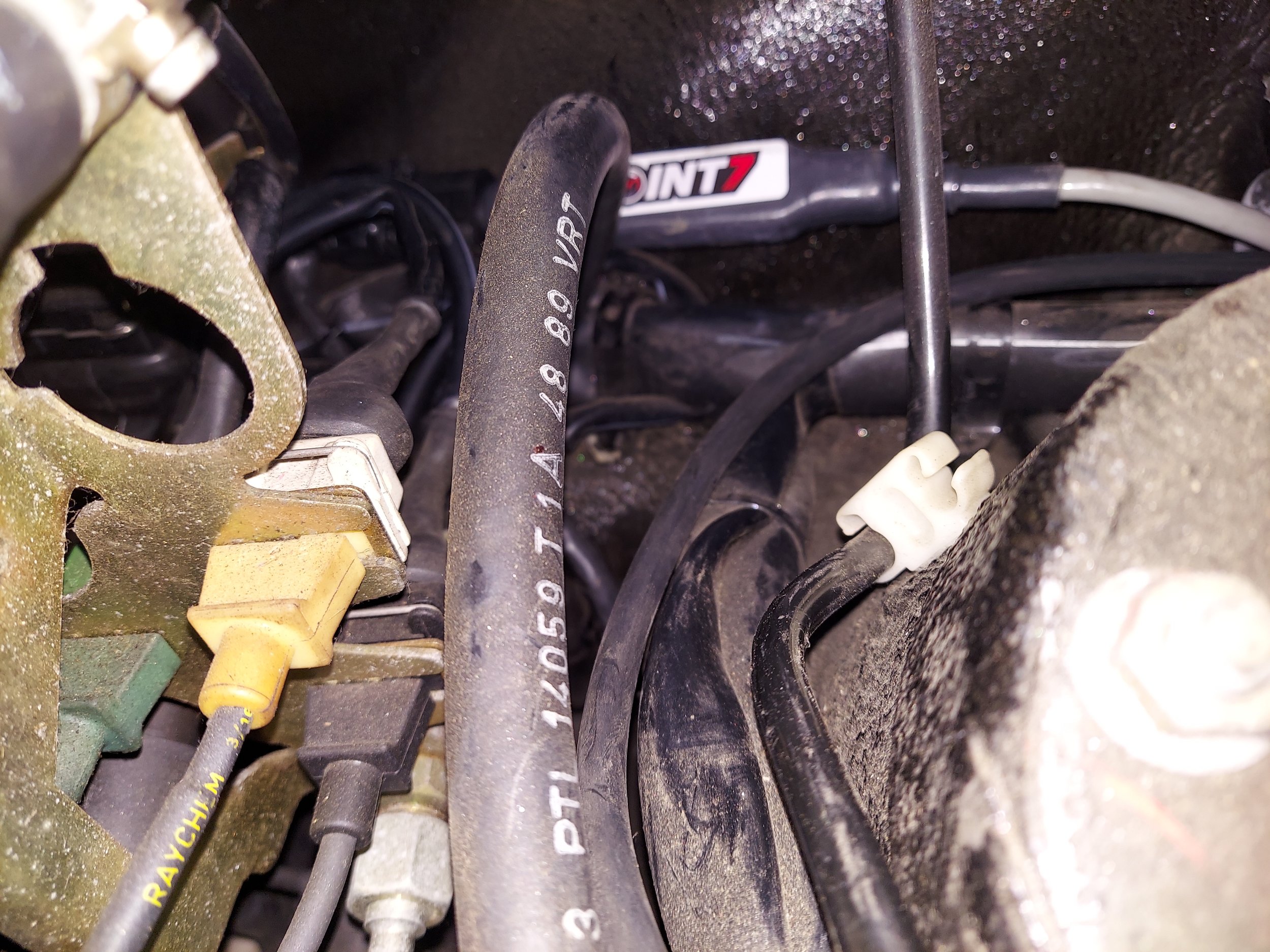

The vac hose will get tee into the vac line on the intake manifold that supplies vac for the res flap. It is the hose with the vac check valve inline (small black or blue/white canister in pic). The tee must be installed before the check valve on the hose coming right off the intake manifold.

On the basic kit the vac hose will run into the car to the ecu.

On the easy install kit the vac hose will get run to the external map sensor. On the easy install kit the vac hose is large to go over the external map sensor. Zip tie the hose onto the tee fitting and the map sensor

-

On the easy install kit with stock afm in place, this adapter will get plugged into your original afm connector and the connector with the orange and white wire will plug into your afm.

-

On the easy install kit that the afm is going to be removed on, this adapter will be used. The 2 pin connector with orange and white wire is for the iat sensor. The kit will come with an iat with or without threads.

The iat without threads can use a simple grommet to mount in your afm delete tube.

The iat with threads has m12×1.5 threads. You can drill/tap your afm delete tube to mount

-

This adapter is for the basic kit with afm removed. The kit will come with an iat with or without threads.

The iat without threads can use a simple grommet to mount in your afm delete tube.

The iat with threads has m12×1.5 threads. You can drill/tap your afm delete tube to mount

-

Pins 2 and 3 need to be de pinned and swapped on the ignition distributor. These are the white and brown wires. Some connectors have heat shrink over the connector under the boot seal it is easiest to heat the shrink wrap up to cut off.

If this is not done the engine will still start and run, but a cam fault will be present in the ecu

-

Unplug the throttle body switches on stock 964 throttle body. These will not be used.

If you are running a newer throttle body with tps you can leave this connected as the wires have been setup for tps.

-

On the basic kit or kits with add on options, the wiring for o2 sensors and vac hose will be run through the firewall and follow the stock engine harness to the ecu

-

The step plate will need to be removed to lift the carpet. Harness routing under carpet following stock engine harness

-

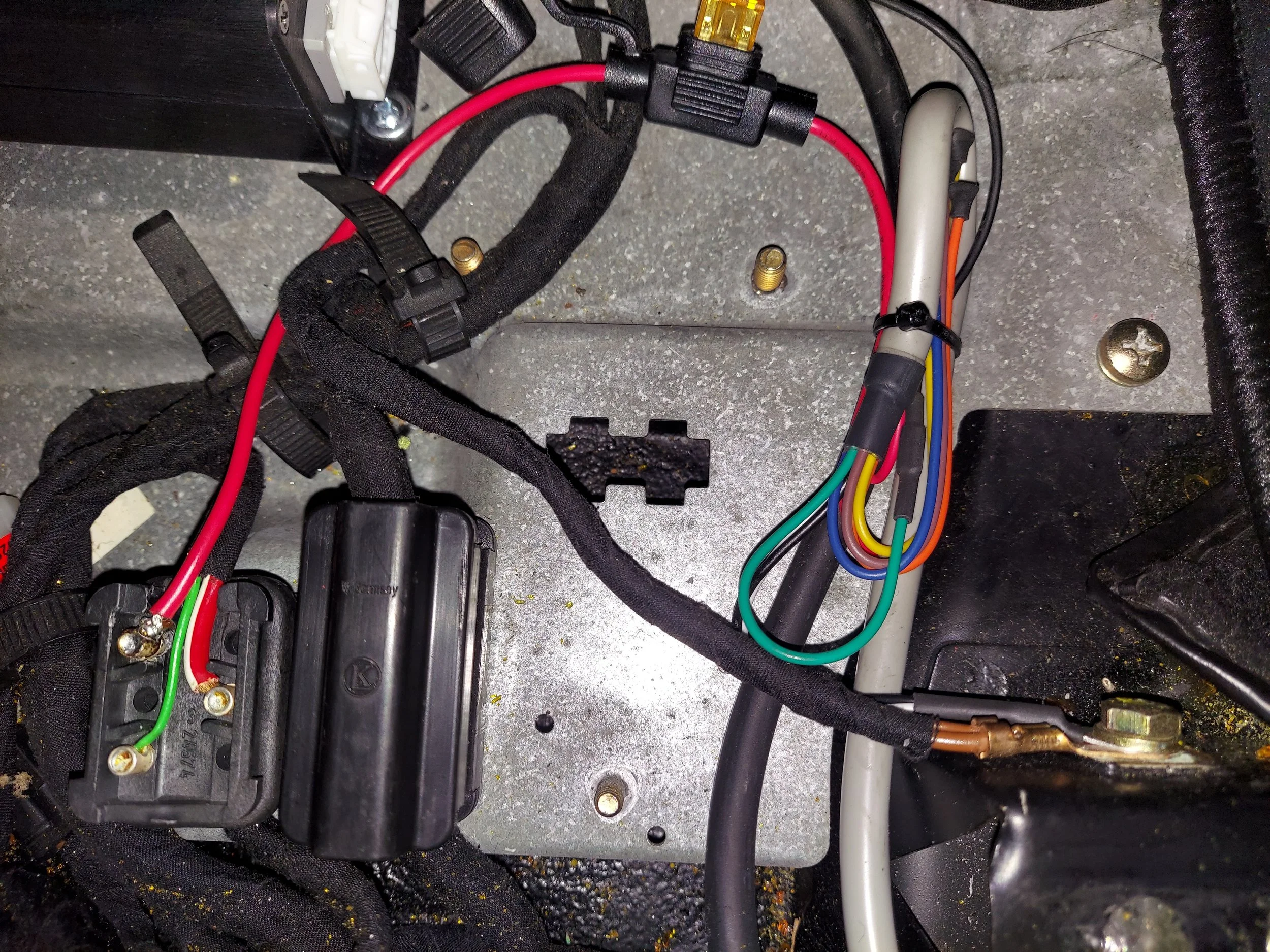

The ecu will be mounted to the ecu mount plate with zip screws. Plug the ecu in first to the dme connector to mark out the area for the zip screws.

On basic kits the vac hose will slip onto the vac barb on the back of the ecu. Lube the hose and push it on over the threads. I recommend to zip tie also.

You can plug in the ecu data com cable

-

On the basic kits the o2 sensor wiring will need to be hooked up. The harness is long and can be trimmed back if wanted. The red wire for the o2 controller is power, this will go to the fuse holder supplied and then to a key on power source.

The closet key on power source is the large 3 pin connector mounted to the ecu plate. You will need to remove the cover and red pin to solder the fuse holder power wire to the pin. Do not do this with the pin in place on the connector as it will melt the plastic

-

On the basic kits the o2 sensor wiring will need to be hooked up. The black and white wires are the ground wires for the o2 controller. Slide the heat shrink over the wires then crimp the ring terminal supplied. The ring terminal can get connected to the chassis ground

-

On the basic kits the o2 sensor wiring will need to be hooked up. The green wire is the controller signal wire to the ecu. This will connect to the accessory pin G on the back of the ecu.

The rest of the wires for the controller are not used

-

Accessory pin out on back of ecu. Pay attention to the connector orientation

-

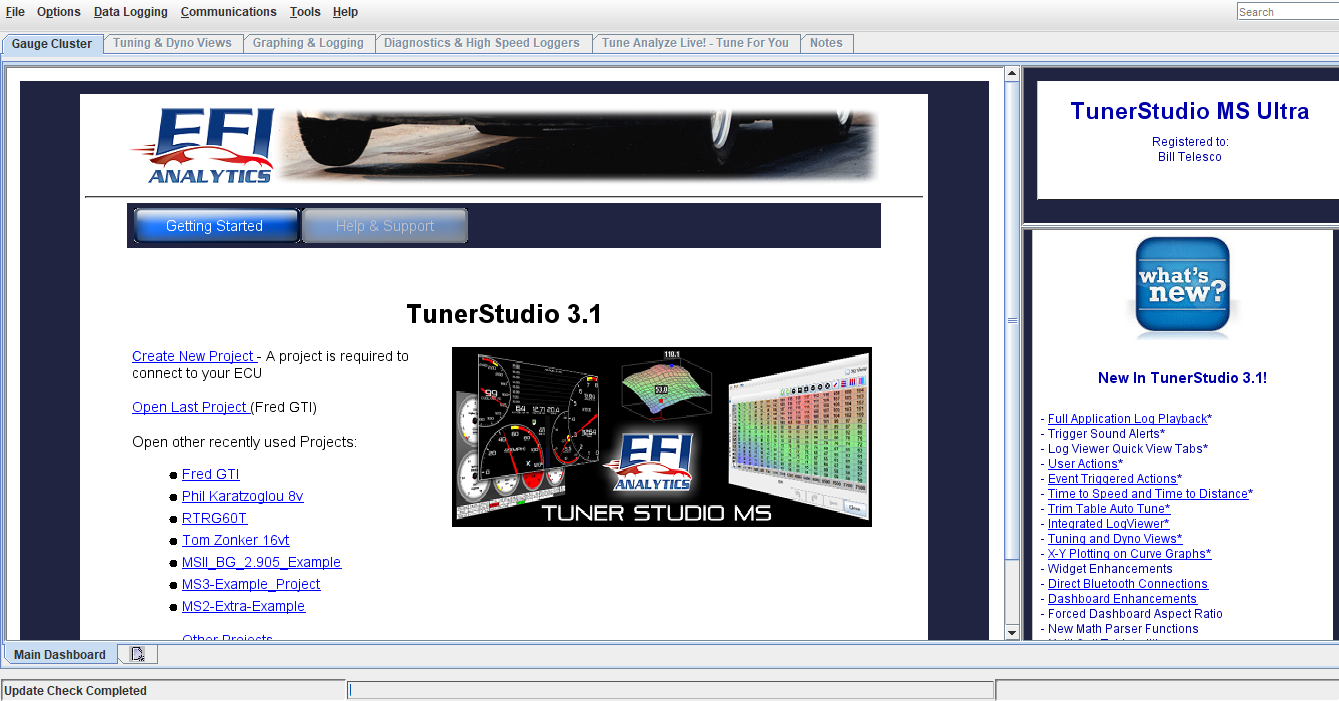

Open the tuner studio software. link http://www.tunerstudio.com/index.php/downloads

This is the main page. Click create new project

-

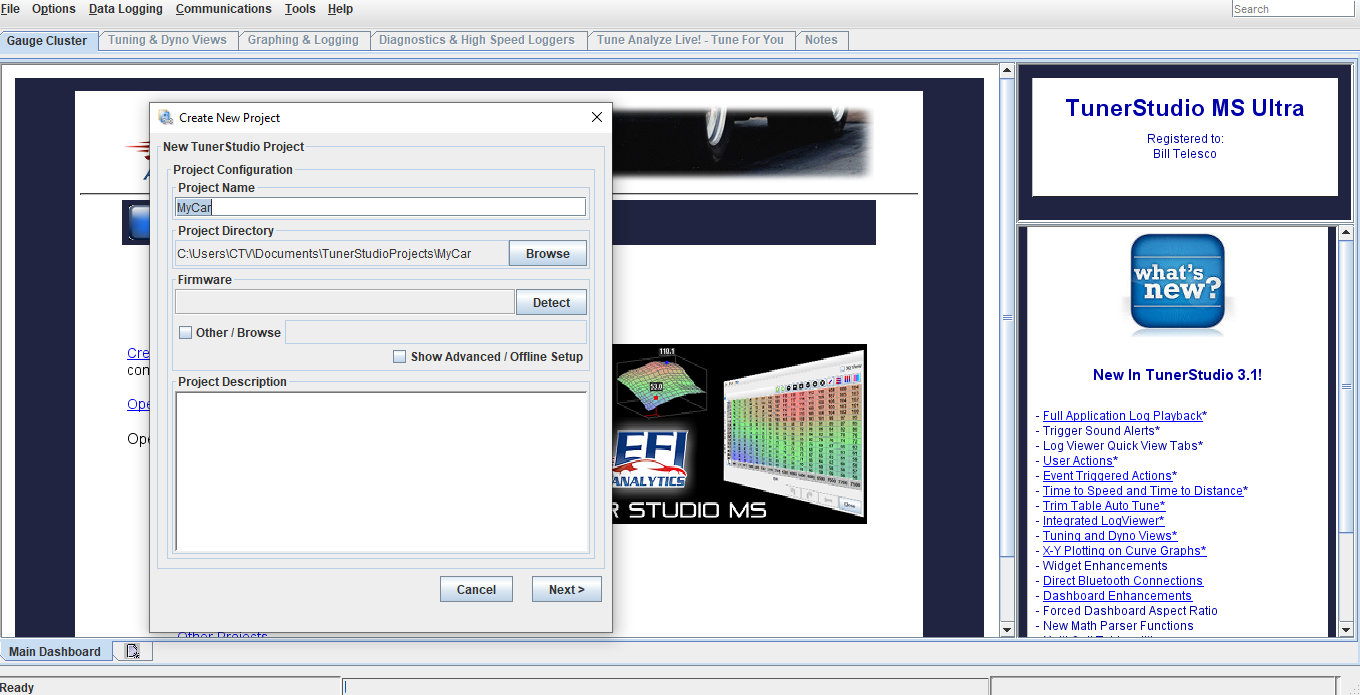

Add project name. Click detect, this will search for the ecu. Key must be in on position to power up ecu and the data cable hooked to the ecu with serial to usb adapter hooked up to your laptop/tuning computer. If it does not detect, you will probably need to download the driver file for the usb adapter or change the communication baud rate (it is usually a driver file missing). I have made sure to bench tested all the cables, sensors, and harness in your kit directly with your ecu before shipping.

-

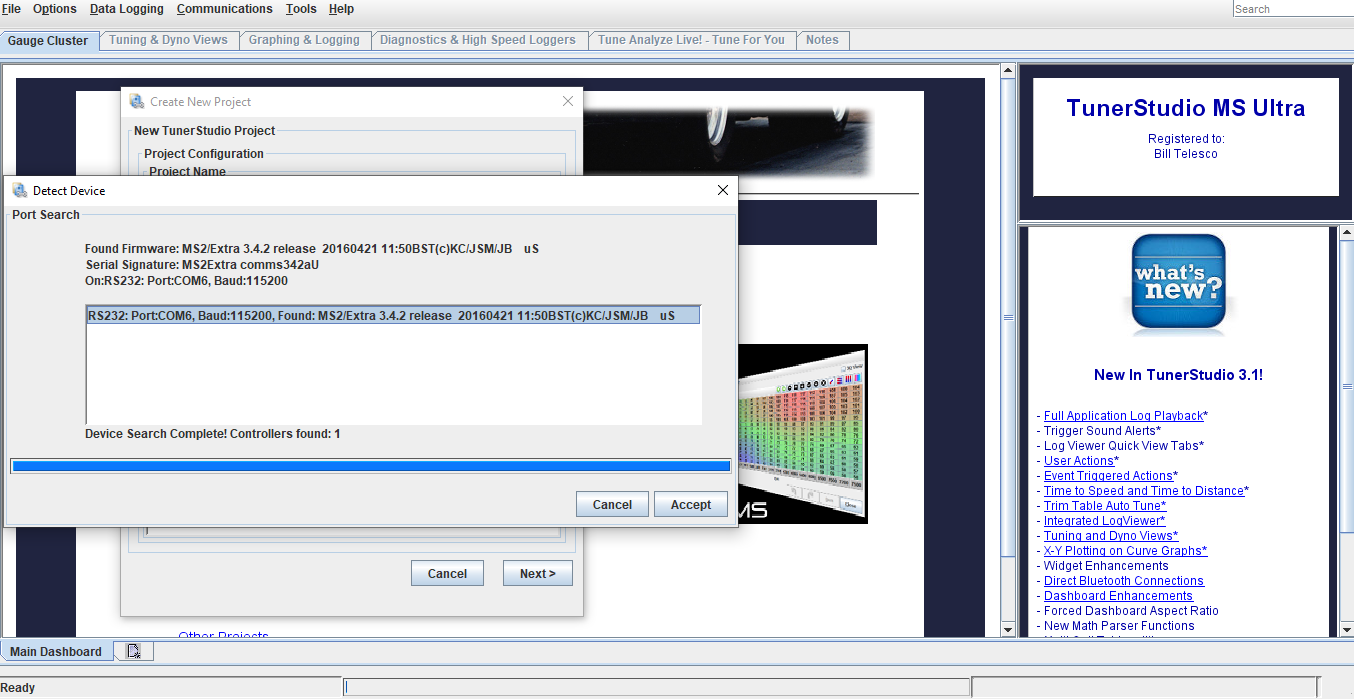

Once ecu has been detected, click accept, then click next

-

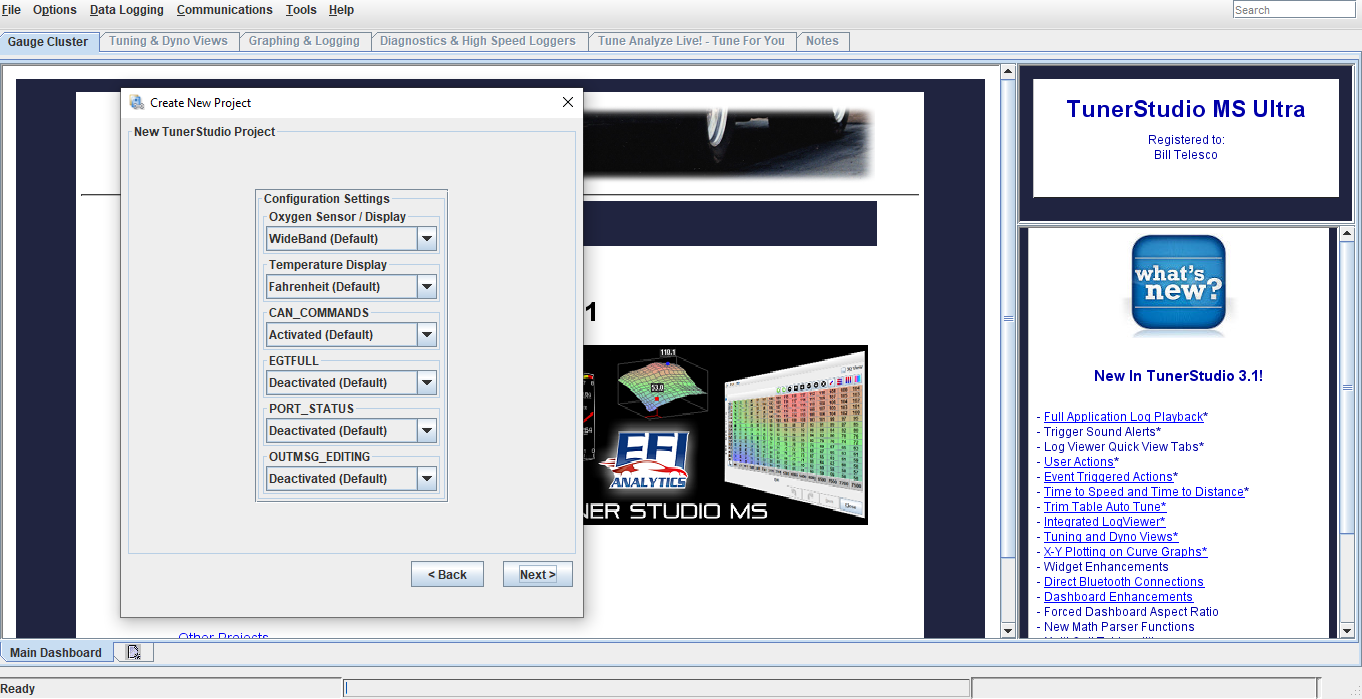

Next screen is Configuration settings. These do not need to be touch, the default settings are good. Click next

-

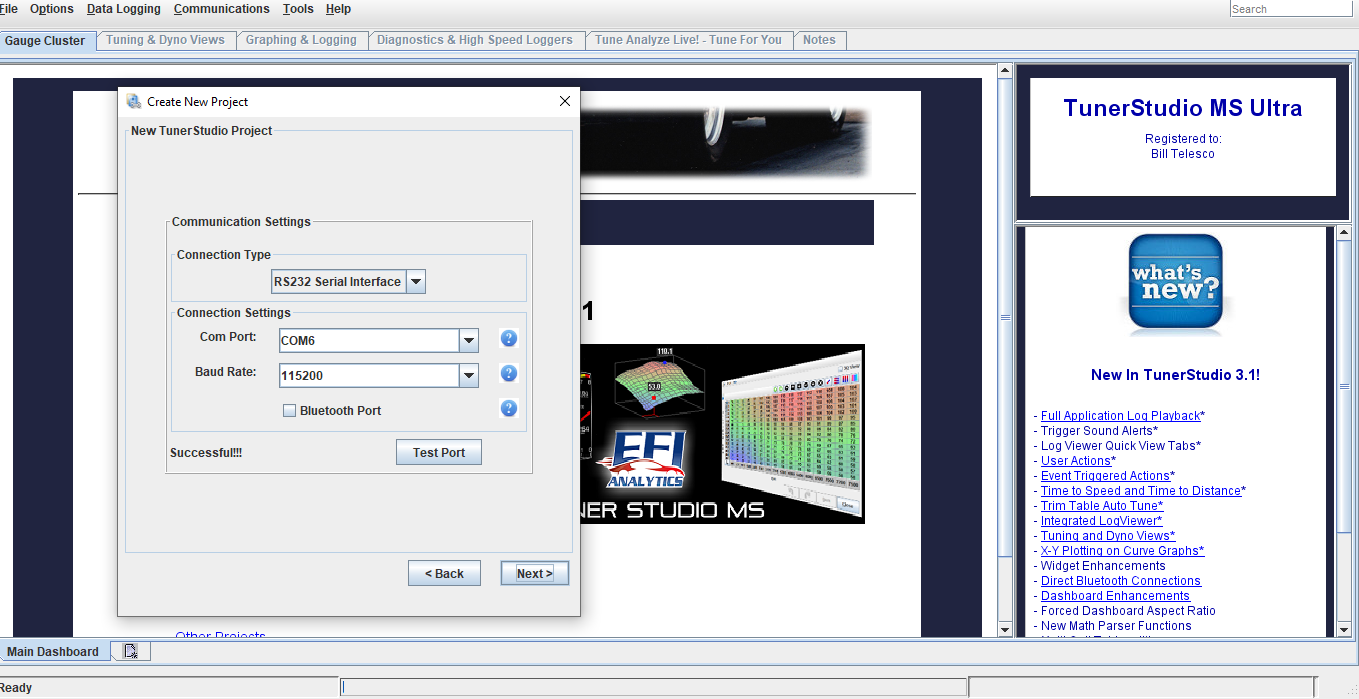

Next screen is Communication settings. Click test port, it should come back successful. Click next

-

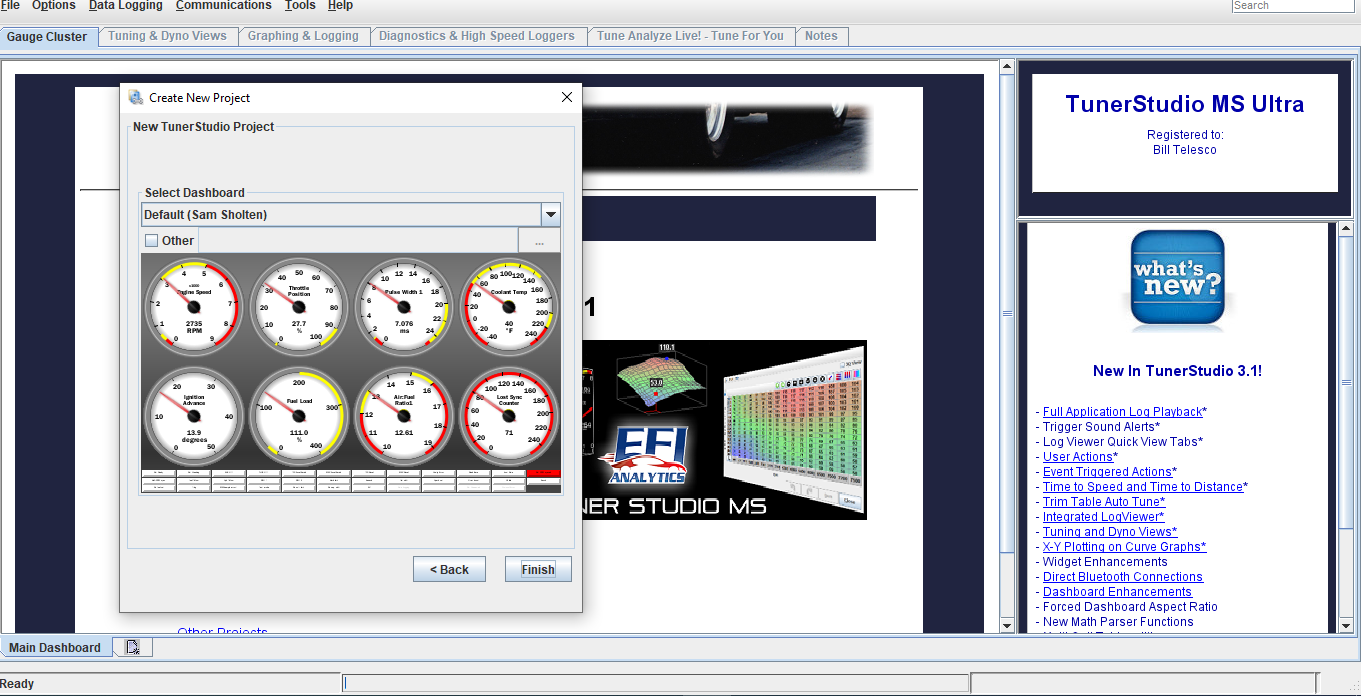

Next screen is dashboard. This is the gauge display you will see once the ecu has been connected to tuner studio. You can leave it on default, but I recommend downloading the dashboard display I have emailed over with the base file copy and installing that. To do that check other, then click the 3 dots in the right corner to browse for the file download.

Note: If using the lite free version this option will not work

-

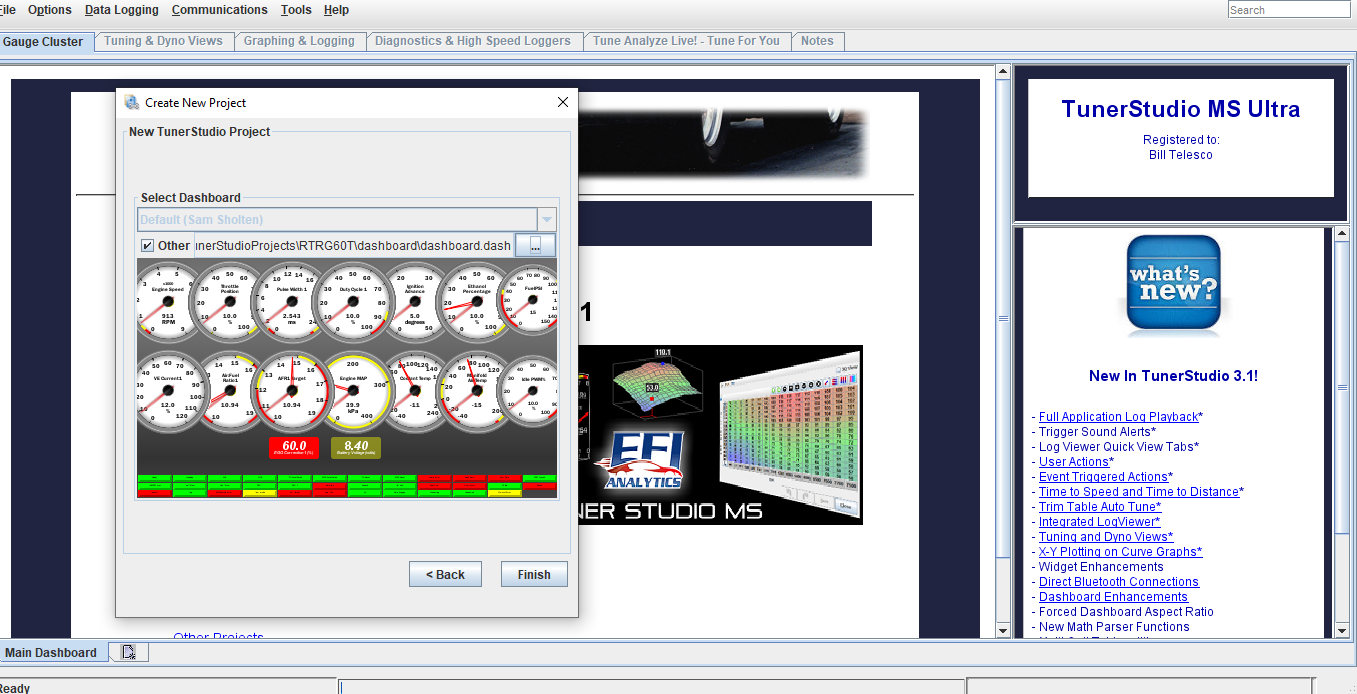

Once new dashboard has been downloaded, you’ll see there’s a lot more gauges for viewing data added. Click finish and that will conclude the initial setup

-

You will now be able to see your dashboard gauges. If you have chosen to download the custom dash display I sent over, there are a lot more gauge with the important data.

-

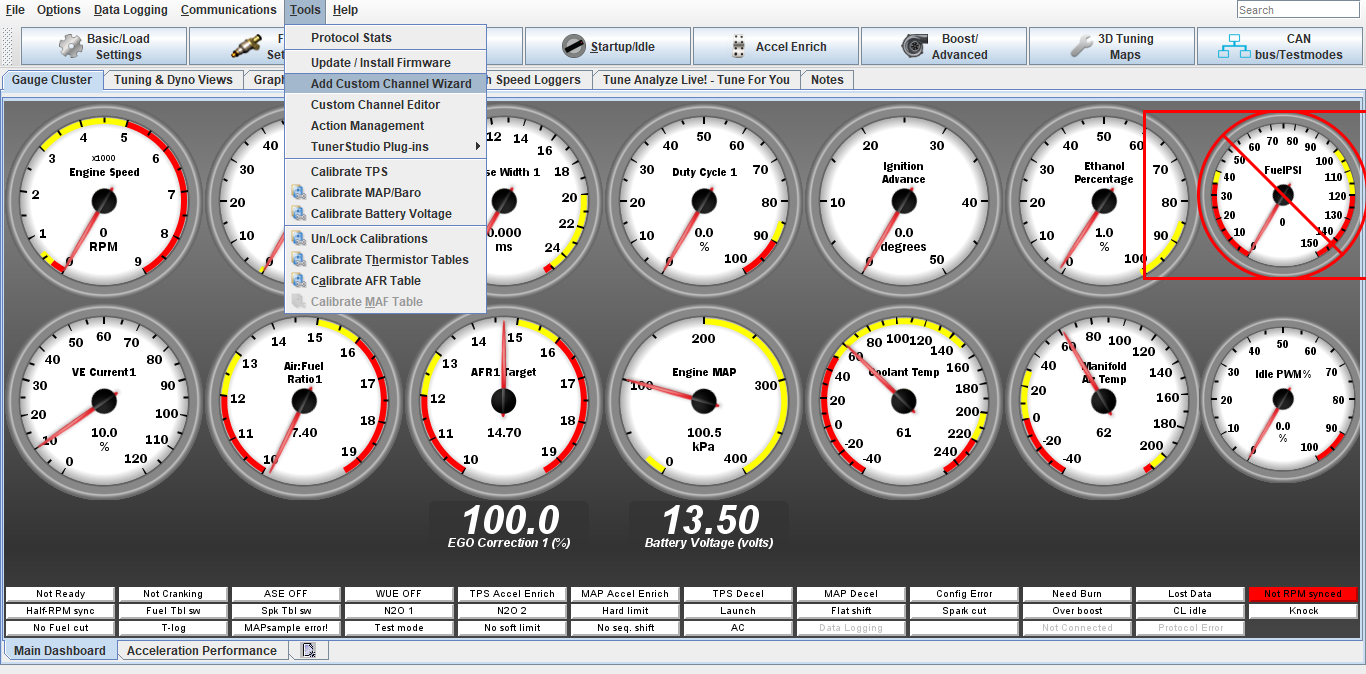

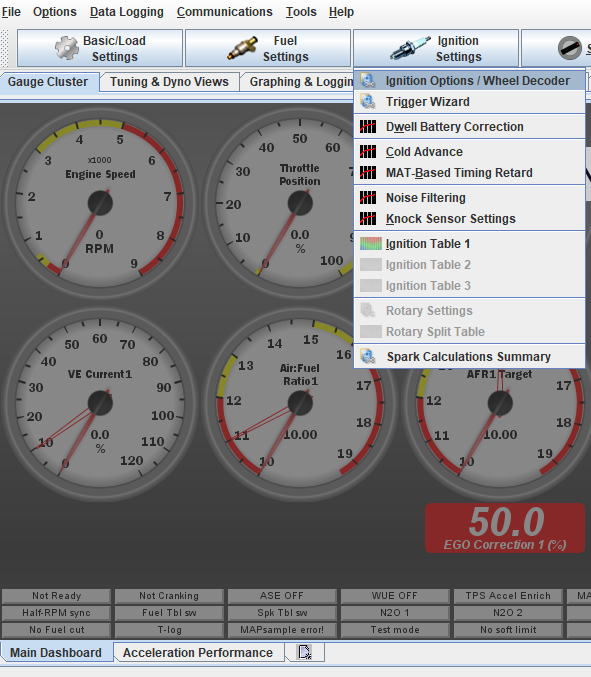

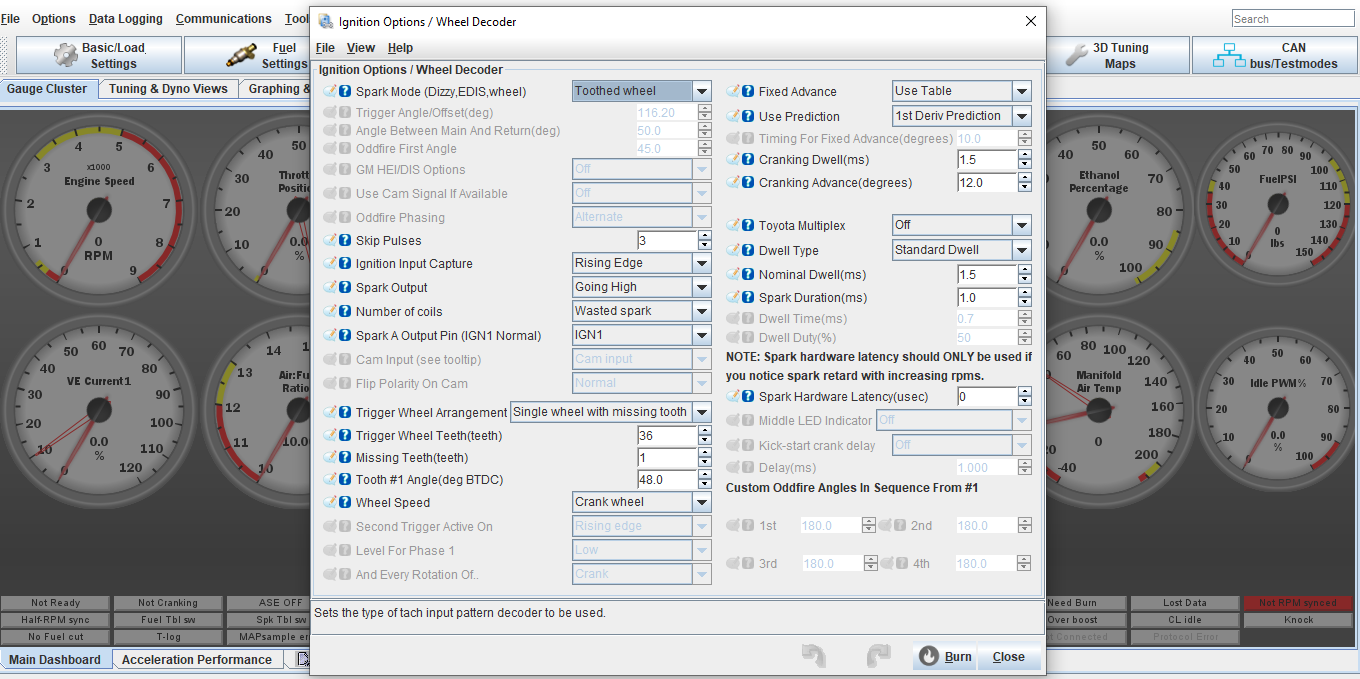

The next step is recommended, ignition timing must be checked/set with a timing light. To do this we are going to go into the the software and lock the ignition at a set degree. On the main dashboard click the Ignition Settings tab, then ignition options

-

In ignition settings, under fixed advance, switch from user table to fixed timing. Now check Timing for fixed advance (degrees), it should already be set at 10, if not type in 10 for 10 degrees, Hit burn. You should hear the car idle down some since timing has now been retarded. You can now verify that the Tooth #1 angle is set correctly by checking timing with a timing light. The timing light and marks should read/line up 10*, if not adjust the Tooth #1 angle setting until the timing marks line up on the flywheel/bellhousing. Once timing is set and verified, go back into ignition settings and switch from fixed timing back to user table, hit burn.

AGAIN DO NOT SKIP THIS STEP!!!!!

-

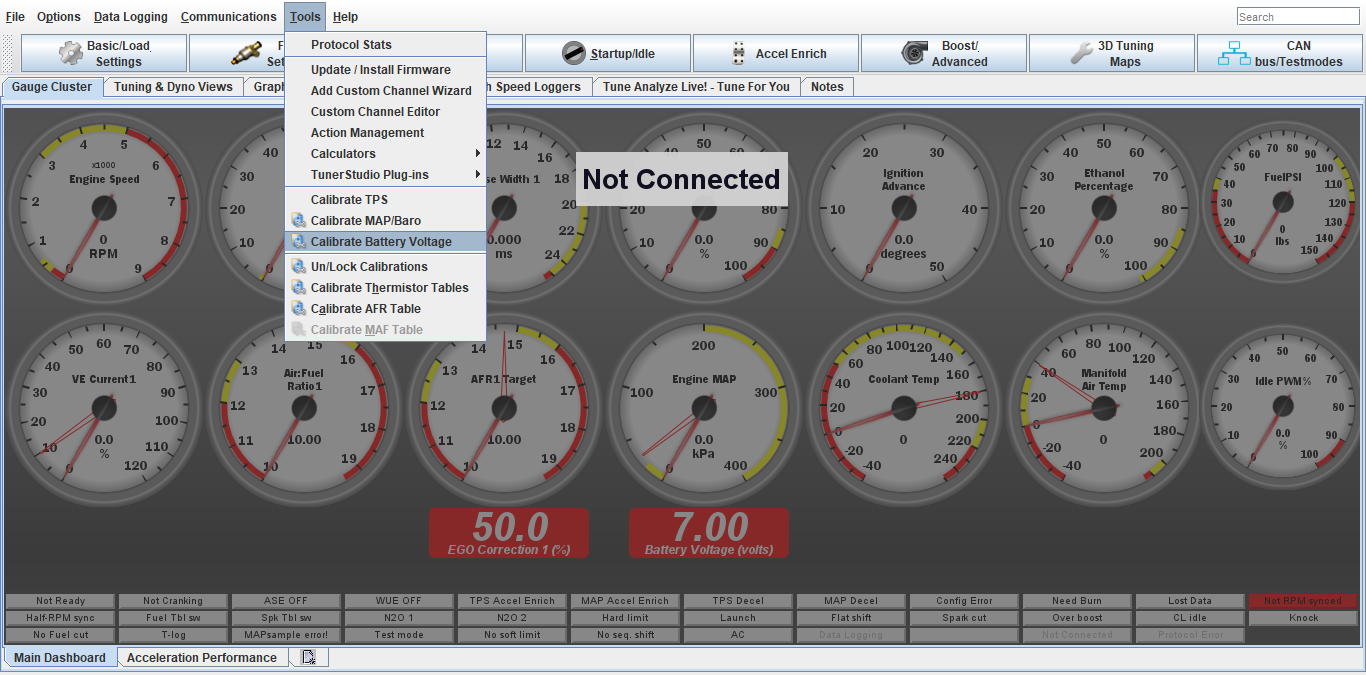

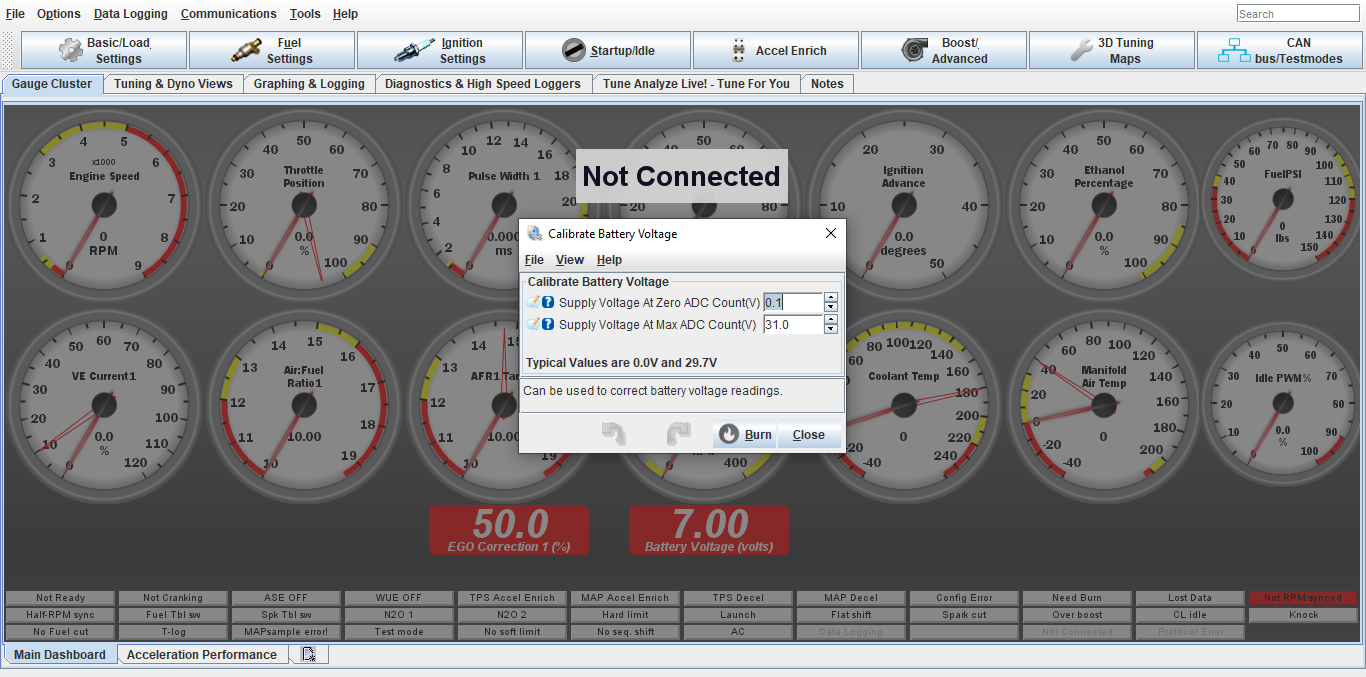

Next is to check the battery voltage calibration. This will directly affect the fuel mixture as a whole.

Click tools, Calibrate Battery Voltage

-

Using a voltmeter, check at the battery what voltage is and compare to the battery voltage reading on the ecu dash display.

DO NOT use the dash/center console gauge as a reading.

Adjust the Supply Voltage Max up/down if needed. The ecu battery voltage will be always fluctuating, so just get it close to the voltmeter reading

-

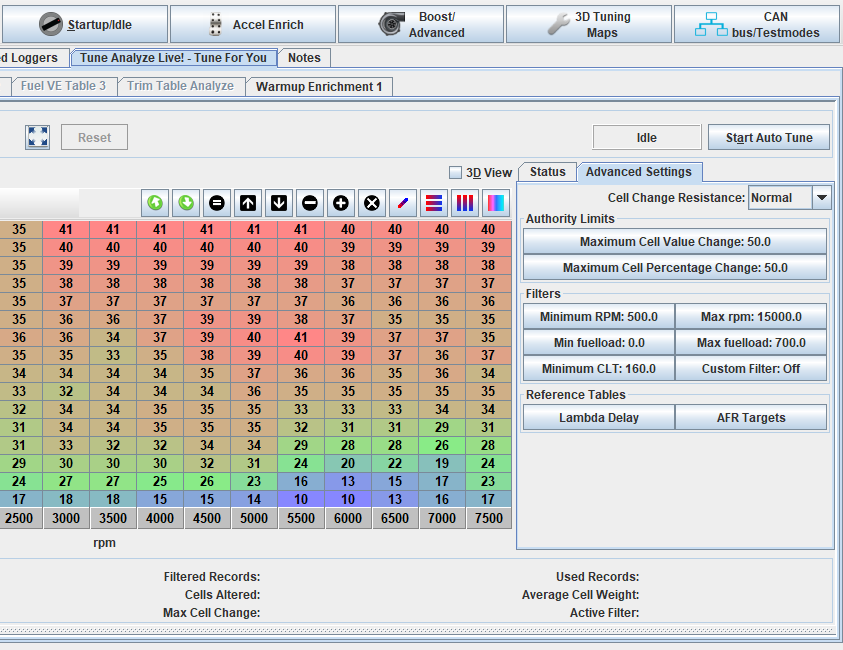

Now that timing is set and battery cal checked, the car should be warmed up and it’s time to start dialing in the fuel with the autotune feature. On the main dashboard click Tune Analyzer Live, then advanced settings. The autotune won’t work unless the coolant temp is above the minimum clt temp. This should be set to 140-160*. If your engine is above those temps (which can be checked on the main dashboard) click start autotune. You will see the tracer moving and correcting cells in the fuel map. Click on the status bar, you will see in cell weighting the chart changing color, once you see dark green in those areas, fuel should be dialed in to the settings on the afr chart (I have preset the afr settings in the fuel settings)

-

Once idle afr is dialed in its time to start driving the car and letting the autotune do its magic. Drive the car around, IN A NORMAL CONTROLED MANNER, around town and on the highway. You will see colors start popping up in the cell weighting area. Once the cell weighting is dark green in those areas on the you can start doing full throttle pulls. Note that the tracer will only hit certain load areas, this is normal. Keep an eye on your o2 gauge to see where afr is at.

AFR targets: Idle 13.6 on most apps, Cruising and around town 13.8-14.5, full throttle NA engines 12.8-13.3.

Full throttle on boosted engines 11.2-11.8.

Start on the lowest boost setting possible and work your way up.

On boosted apps don’t go for broke and just start hammering it full throttle, do easy progressive pulls so the ecu can correct the fuel. If you see lean mixture, get out of the throttle, wait a few seconds then do another pull. On turbo apps pay attention to your intake temps when doing pulls. Try not to go over 120*f. When your finished tuning click apply/burn/save on ecu, then save on ecu. This will burn the autotune changes to the ecu. Turn the autotune off when done.

Save a copy of config file as a backup as well under file, save config. Files and logs will be stored in Documents under Tuner Studio.

If you are uncertain at any time or uncomfortable with tuning, contact us and we will help get you sorted.

DONT BE STUPID, you can hurt your engine very easy with lean afr, Ping/Knock and full throttle driving like speed racer, especially under boost.

-

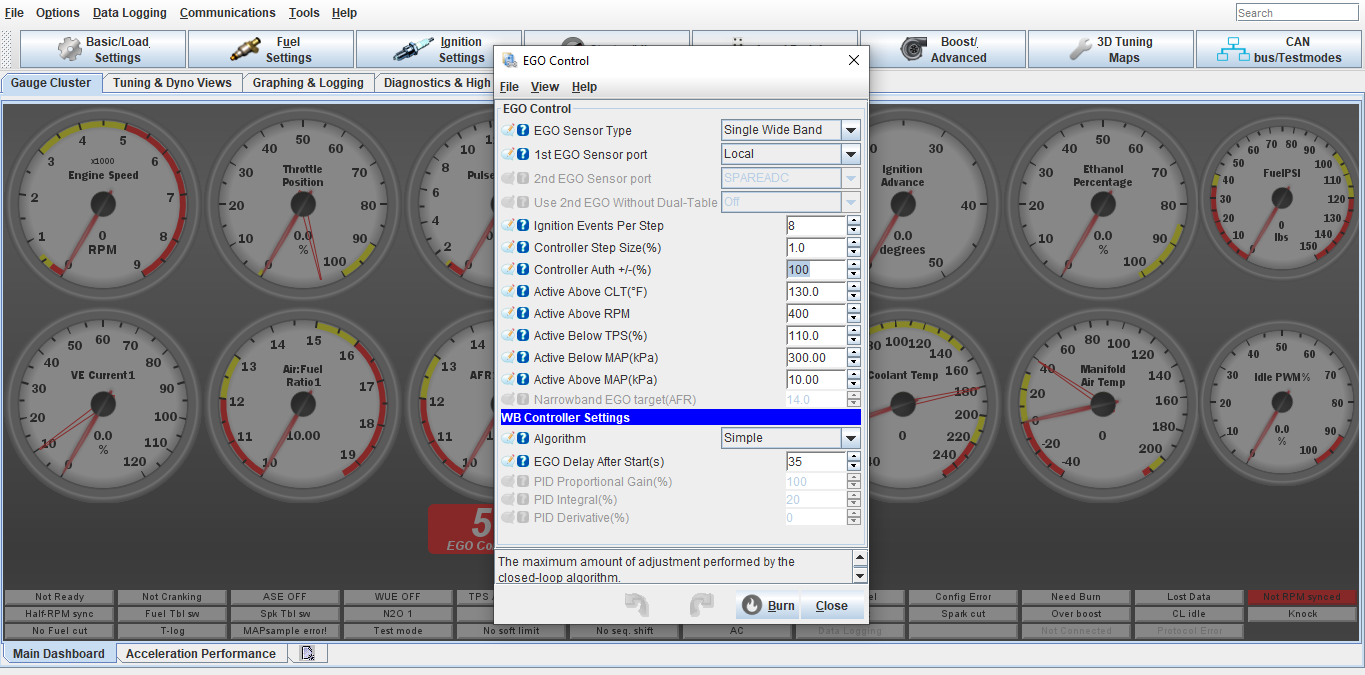

Once your warm engine tune has been complete we can turn the EGO/O2 correction control percentage down. It has been set to 100% in order to make tuning easier.

Go into Fuel Settings, Ego Control, and turn Controller Authority down to 20%

Click Burn

-

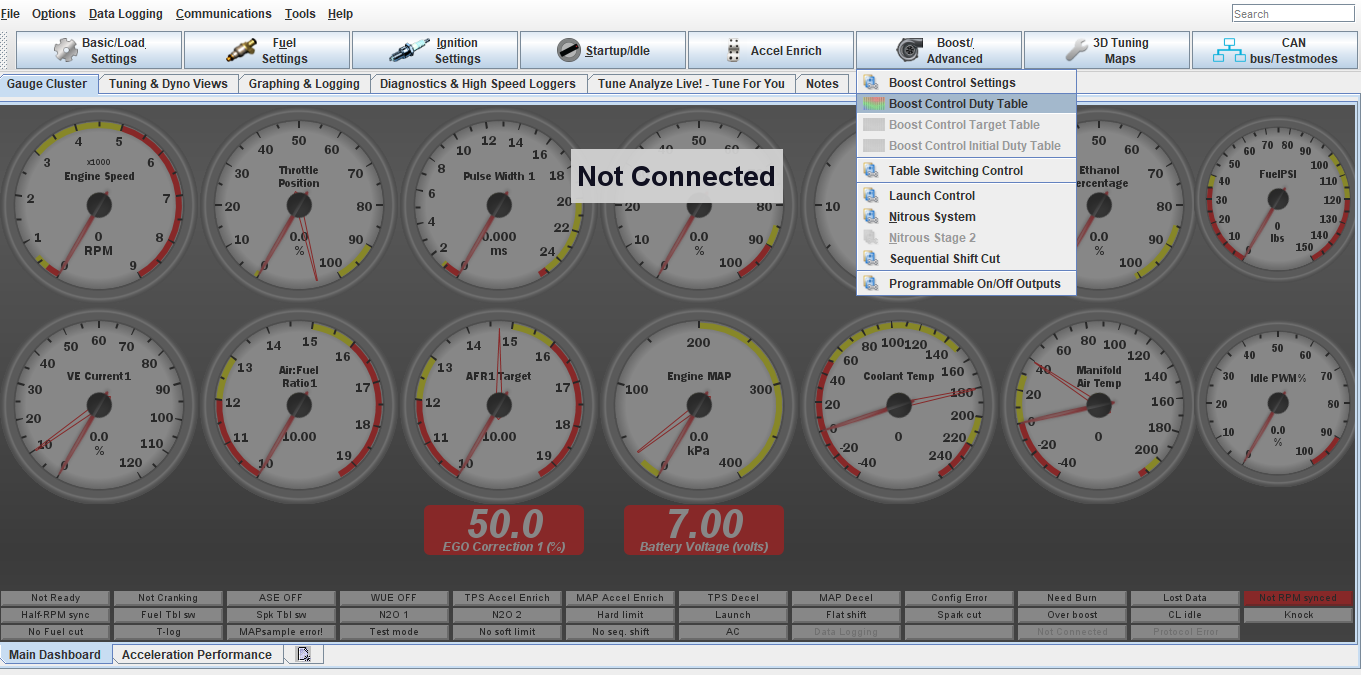

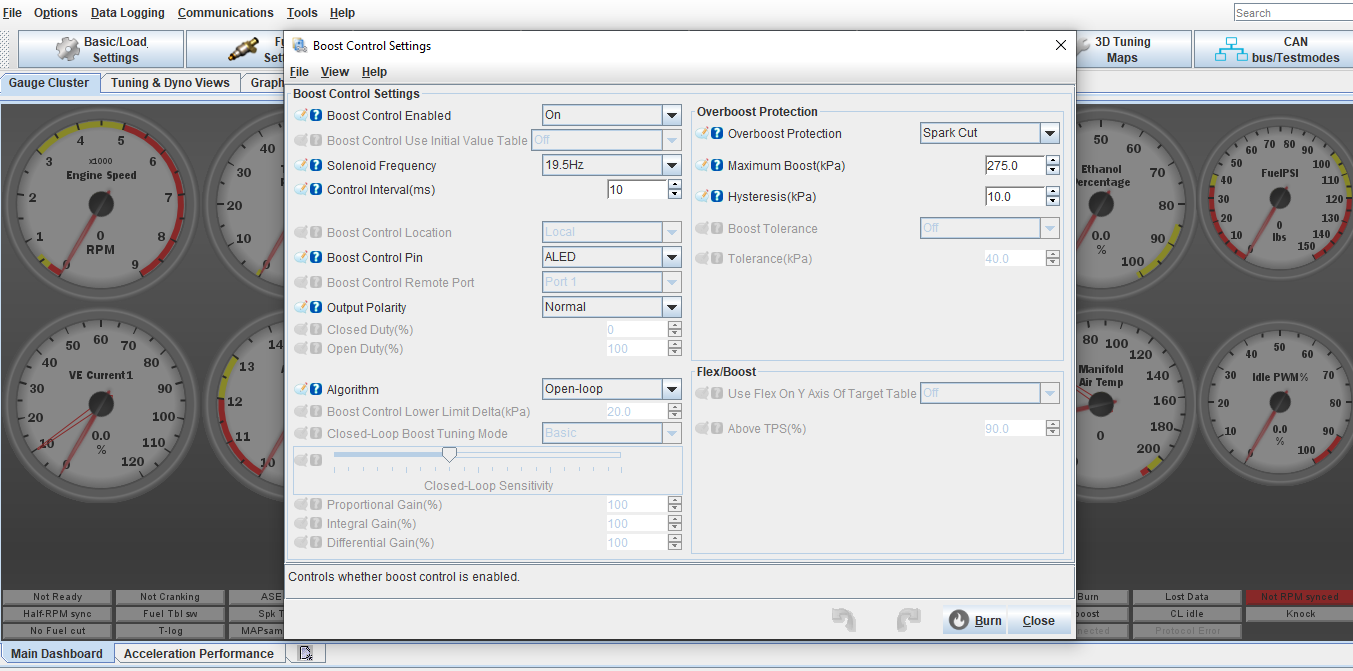

If your setup is turbo and using the electronic boost control, we can setup the safeties and boost control.

Click Boost/Advance tab, Boost Control Settings

-

Copy the settings on this screen. Work with the open loop setting first until you understand how the boost control works. From there you can setup a closed loop map if wanted.

For Over boost Protection, set this about 5-8lbs higher than the max boost you would like to run. I will usually pre set this based on our consultation about your setup

-

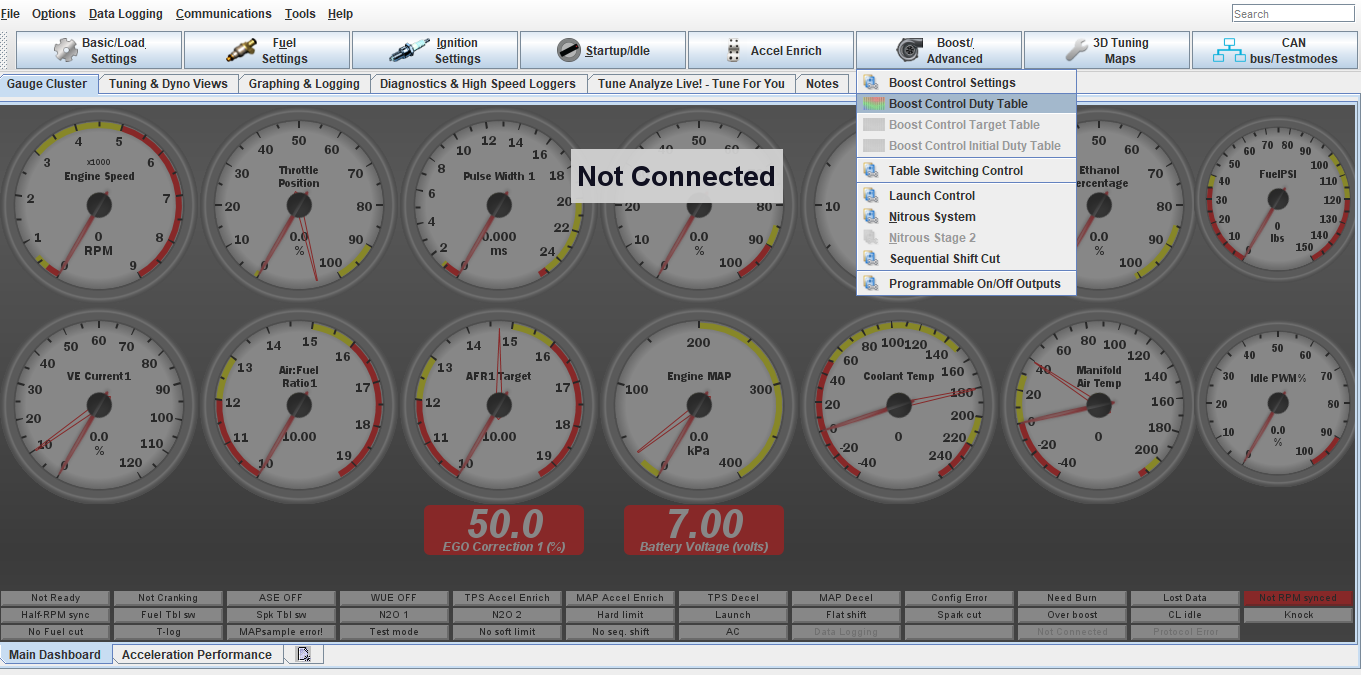

Next is to setup the open loop table. Click the Boost/Advance tab, Boost Control Duty Table

-

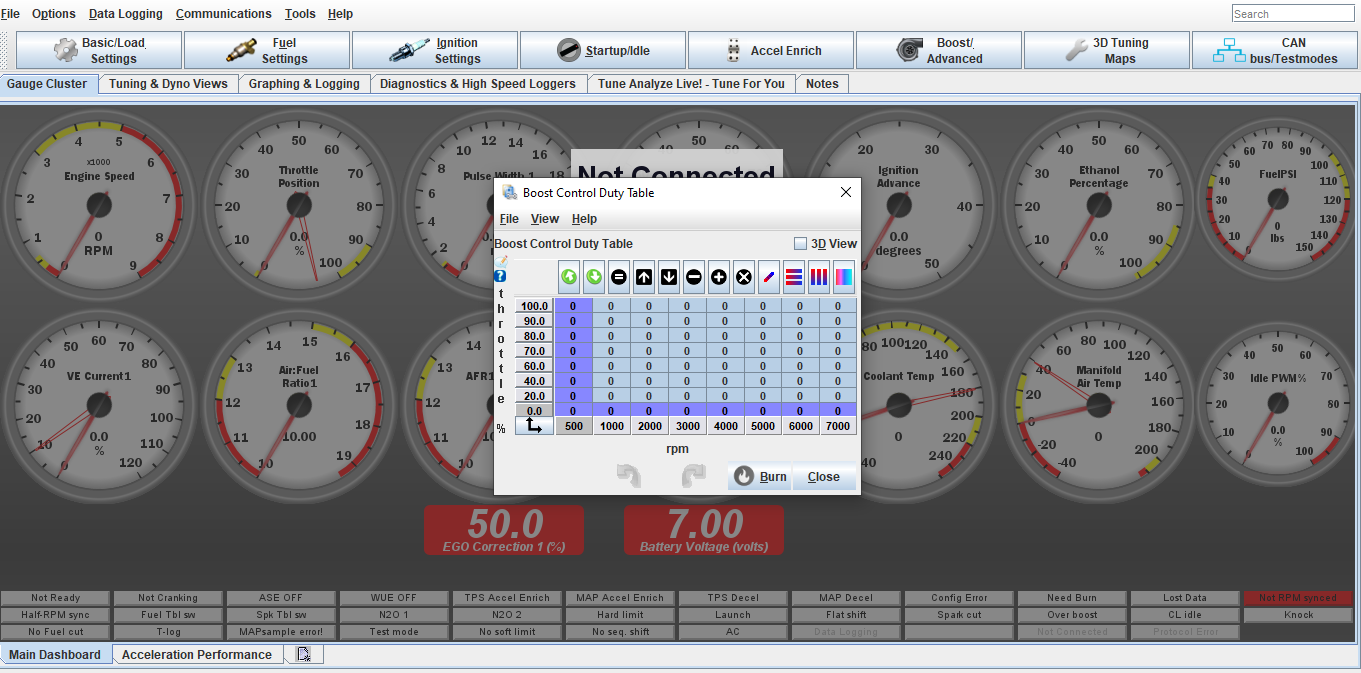

This table will be set at your discretion. This is direct duty cycle% control on the solenoid. Max duty cycle should not go over 85%.

It is best to start off with the way the table is highlighted and increase the cells in 5-10% changes until you figure out how much the % vs boost is. From there you can build a curve and ramp boost up/down vs desired power/boost level or to act as traction control for wheel spin. This is where the data logging is very useful

-

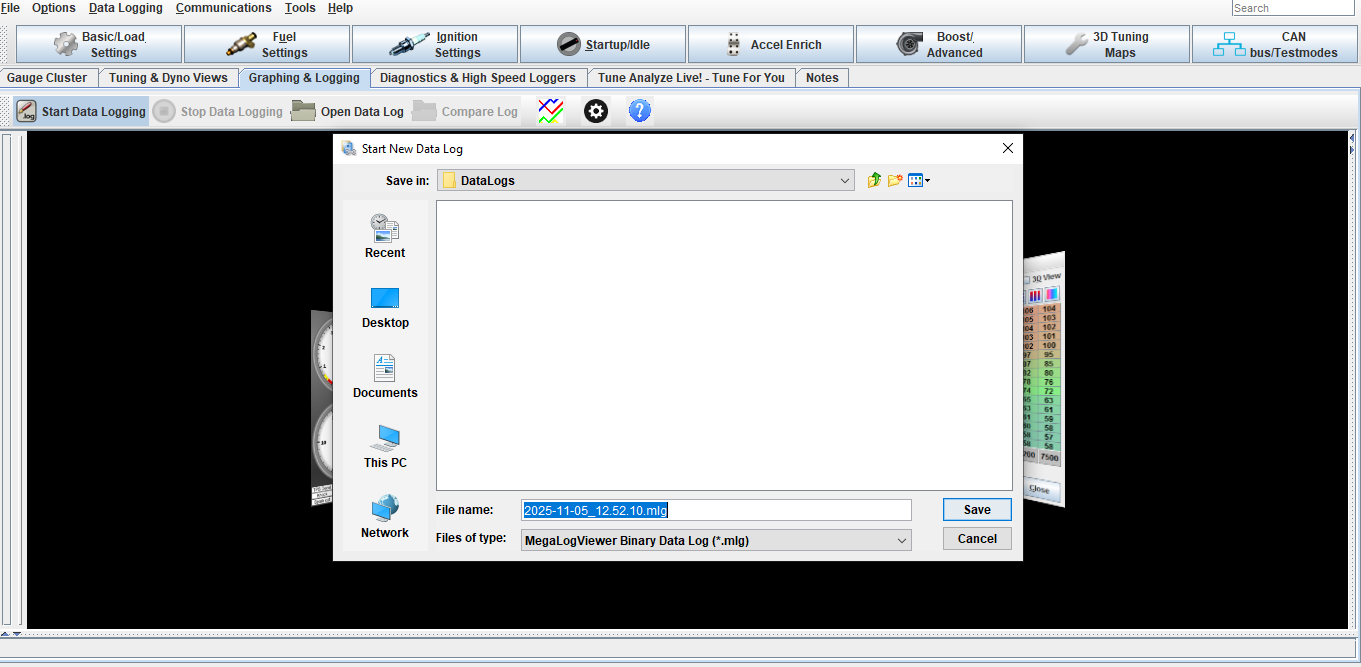

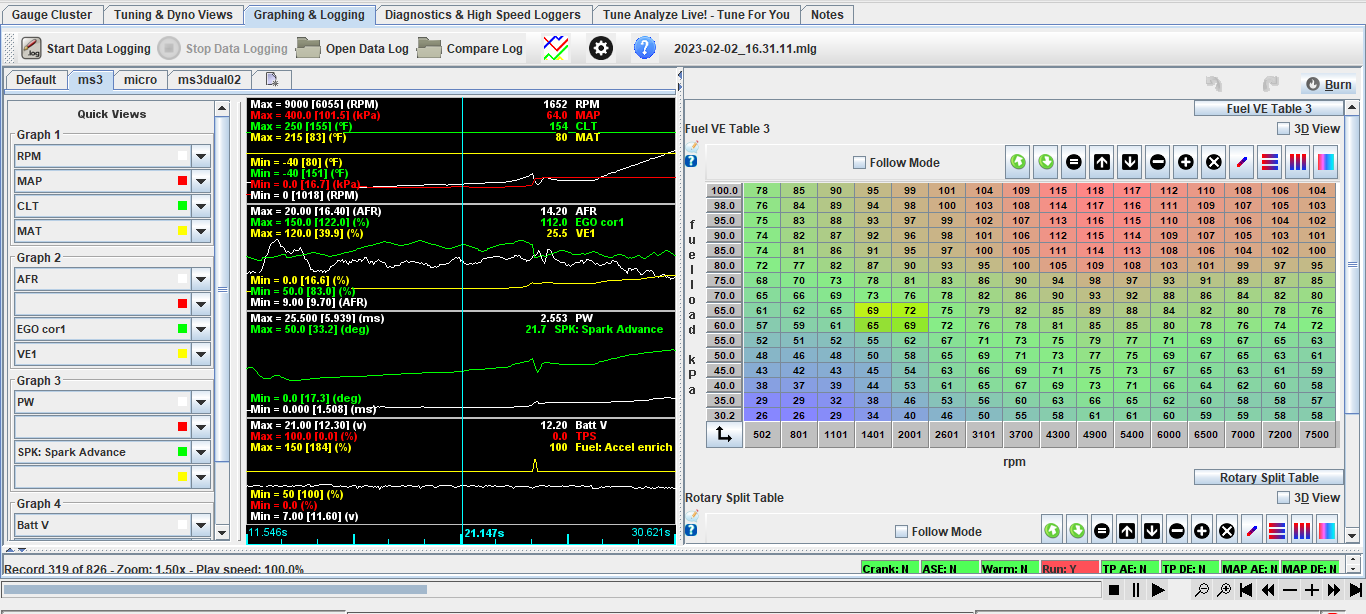

To Data log click Graphing and Logging tab, Start Data logging, Click save on the pop up screen, Click Stop Data logging when done.

The log will stay open on the screen.

To open an old data log click open data log and select your file

-

Select the data you would like to view in the log. You can save your data view list by clicking the quick view tab window in the corner. This saves time from having to setup the list every time you view a log